Forged vs. Cast Pistons

Piston selection is a critical step during the engine build process; pistons are the backbone of any true performance engine. Not only is it crucial to choose the right bore and compression ratio configuration, but it is also key to select the best material for your application.

The two main piston types available on the market are forged and cast. To understand the difference between the two, we’re going to break down a few key points, including material composition and manufacturing process.

Forged Pistons

Forged pistons start as a solid piece of aluminum which is pre-worked to remove any voids or imperfections from the metal after it solidifies. This piece of solid aluminum is then heated and formed into shape by a press, creating the piston.

A major benefit of forging is that the material used can be carefully selected from specific stock for additional strength and quality.

Cast Pistons

Cast pistons are created by pouring melted metal, such as low carbon steel or [more commonly] aluminum alloy, into a piston-shaped mold. This results in a cheaper, lighter piston.

The Differences

Grain Flow

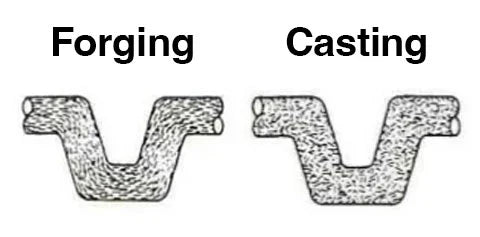

One of the key differences between forged and cast pistons is what is known as ‘Grain Flow.’ Grain flow refers to the orientation of the grains metal is composed of and determines piston quality and strength. In short, cast pistons are not as strong as forged pistons.

Grain Flow and Grain Structure directly affect the materials mechanical properties as they determines the direction that the underlying grains push/pull under stress and fatigue.

Photo Courtesy of Trenton Forging

Optimal grain flow is when the direction of the grain structure aligns with the stress requirements of the piston. When the metal used to make forged pistons is pre-worked, the individual grains of the metal composition are elongated and aligned longitudinally.

CP-Carrillo uses 2618-T61 Aluminum Alloy, a high-strength alloy known for its corrosion resistance properties and favored for its ability to absorb extreme heat while taking minimal damage.

During the forging process, the aluminum used to make pistons is heated and undergoes what is known as ‘controlled deformation.’ Controlled deformation is when the aluminum used to make the piston is carefully warmed to the point where its shape can be formed into a piston. The benefit of controlled deformation and forging is that grain flow can be controlled; no matter how complicated the geometry of the component is, every area of the piston will have continuous grain flow.

Forging produces components with grains deliberately aligned in the direction of maximum strength. As a result, they have exceptional fatigue and impact resistance.

Cast pistons do not have uniform grain structure or grain flow, and as a result they do not have directional strength. During casting, when the melted metal begins to cool in the mold, dendrites form. Dendrites are essentially tree-like crystal structures that form in metals as they solidify, compromising the grain structure of the metal as it cools.

As a result, the grains of cast metals are not uniform, resulting in grain boundary voids. Grain boundary voids compromise the impact and fatigue resistance of the cast piston, meaning they are not as strong as a forged piston.

Weight

Mentioned above, cast pistons are typically lighter than forged pistons. However, they lack the material structure and strength of forged pistons, making them much weaker. While heavier, forged pistons are much more equipped to handle the high horsepower, boost, and RPM demands of performance engines.

To compensate for the slight weight increase associated with forged manufacturing, CP-Carrillo has developed a method of production and piston design known as X-Forging for lighter forged pistons that maintain structural integrity and strength. More on X-Forging Here.

CP-Carrillo Forged Pistons

CP-Carrillo understands the importance of pistons in high performance engine builds, which is why they have committed themselves to manufacture the highest level of pistons on the market.

CP’s Engineering Department began by analyzing their competition and gathering industry data. Using Reverse Engineering, Design Experience and Flexibility, Analysis, and extensive Research and Development, CP-Carrillo developed the highest quality, highest performing piston available.

Adapting to industry changes, CP is constantly developing application-specific forgings, as well as exclusively manufactured, proprietary treated wrist pins and rings. With each new development, new components go under strict research and development stages to ensure a product that will exceed any standards.

CP’s Engineering is guided by the belief that, ‘As in racing, it takes a lot to be number one; CP has it all and is number one in piston design, enabling our customers to come in first on race day.’